Reprinted from TEC 48 Issue 6 (JUNE 2007)

L D HOWE

National Traffic Control Centre (NTCC), 3 Ridgeway, Quinton Business Park, Quinton Parkway, Birmingham, B32 1AF

PACS Numbers: 02.70.Lq, 02.70.Rw, 46.90.+s, 89.40.+k

Key Words: traffic, highway, simulation, modelling

The National Traffic Control Centre (NTCC) collects traffic data in real time from a network of induction loops. Amongst other things, the data is currently used for assessing the stress on the network. In the future, it is intended that flow data will be used for automatic detection of events involving capacity restriction and demand increases and to estimate travel times under delay conditions. Traditionally, the only way to check the accuracy of flow data has been to make a video recording of the traffic and manually count the vehicles passing a reporting point. However, there are over 4,000 reporting points on the Project Network so checking accuracy in this manner would be very laborious and, given that the majority of data are accurate, would be extremely inefficient. The Long-term Integration Process (LIP) is a method derived from Kirchoff's law for electric current to identify inaccurate flow data. In this case, the currents are vehicle flows at upstream and downstream Reporting Points integrated over a long period of time. Providing all flows are known, including those of traffic joining and leaving the carriageway, if the upstream and downstream flows are different, one or more flows must be inaccurate. Work is currently under way to identify flow data that is reversed vis-à-vis the carriageway that it purports to represent.

The National Traffic Control Centre (NTCC), operated by Serco on behalf of the Highways Agency collects real-time traffic data from across the Project Network, comprising the motorways and trunk roads in England. Traffic flow information is used for a number of purposes, including the MIDAS (Motorway Incident Detection and Automatic Signalling) system used to warn motorists approaching an incident and to protect the back of queues on motorways, and for strategic planning and decision making (such as suitability of diversion routes).

The real-time data also enables the stress on the network to be calculated. Stress is defined as the ratio of the actual flow at a particular point in the network to the capacity (i.e. maximum sustainable flow) at that point. This is currently used to identify congestion, and in the future, it is intended that the flow data will be used for automatic detection of events involving both capacity restriction or demand increases (or both). Following successful simulation results, it is also intended that flow data will be used to estimate travel times under delay conditions.

Traffic flows are calculated from induction loop data. The induction loops, known as monitoring sites, are buried in the road and count the vehicles that pass over them. In addition they can detect vehicle speed, length and carriageway occupancy (the percentage of the road covered by vehicles). The NTCC system calculates flows as vehicles per hour (vph) every five minutes. The points at which traffic flows are assessed are known as Reporting Points. About 30% of Reporting Points have no direct monitoring and use data derived from one or more remote loop sites. If the loop sites generate inaccurate data or if the derivation of the flows is incorrect, the calculated flows will be inaccurate.

Traditionally, the only way to check the accuracy of flow data has been to make a video recording of the traffic and manually count the vehicles passing a reporting point. The counts are then compared with the flow data so that the accuracy of the data can be assessed. However, there are over 4,000 reporting points on the Project Network so checking accuracy in this manner would be very time-consuming and, given that the majority of data are accurate, would be extremely inefficient. NTCC checks a random sample every month, but given the extent of the network, if inaccuracies do exist they could remain undetected for many years. An additional problem associated with video assessment is the possibility of manual counting errors. These could result in an accurate site being assessed as inaccurate and vice versa. Where a site is initially assessed as inaccurate, the counts can be re-checked to eliminate the errors. However, if an inaccurate site is assessed as accurate, it is unlikely to be rechecked and therefore the inaccuracy may not be detected, until it is selected as part of a future random sample.

There are several possible causes of inaccurate flow data.

Any of the above causes may result in inaccurate flow data. Once the inaccuracies have been identified, the causes can be investigated via further analysis and the faults rectified.

The Long-term Integration Process (LIP) is derived from Kirchoff's law for electric current:

The sum of the currents entering a node must equal the sum of the currents exiting a node.

In the case of flow data, the currents are vehicle flows measured at upstream and downstream Reporting Points. The implication of this is that if the upstream and downstream flows are different, there must be a either an unknown sink into which vehicles disappear or an unknown source from which vehicles can join the road. Providing all flows are known, including those of traffic joining and leaving the carriageway, the law is inviolate.

With electrical circuits, the variations in flow are transmitted at a speed close to light speed, so differences between upstream and downstream currents are difficult to detect. However, with traffic, the variations are limited to the maximum speed of the fastest vehicles. Thus, if we compare traffic flows between two Reporting Points, one upstream of the other, there will almost always be slight differences, even if there is no means of joining or leaving the carriageway. But, by integrating the flows over a long period of time, the difference between the two should be extremely small. Where significant differences exist, one or more of the flows must be inaccurate.

Upstream and downstream flow data may not always be available to the required accuracy because it is not possible to measure the entry and exit flows at unmonitored junctions. However, there is another technique that can provide additional confirmation of accuracy. The period of integration used is 168 hours, which is exactly 7 days, which means that diurnal and day of the week variations will all be averaged out. This presents the opportunity to compare opposite flows (e.g. northbound compared with southbound). The reasoning behind this is that if, for example, an average of 3,000 vehicles per hour (vph) are recorded as travelling southwards on the M1 towards London but only 2,000 vph are recorded travelling back throughout the same 7 day period, either 168,000 vehicles have stayed in London or one of the flows is inaccurate.

There is one other valid reason: one third of the vehicles travelling to London return via a different route. However, experience suggests that this is not the case, with a small number of exceptions, such as locations on the Project Network where a flow imbalance occurs. Notable amongst these is the Severn Bridge, where a toll is charged to cross into Wales but not in the opposite direction. The result is that about 20% of the HGV traffic returning from Wales via the Severn Bridge took another route into Wales. Once such a location is known and its effect quantified, it can be used in the same way as before, but using the required factor to compare the opposite flows.

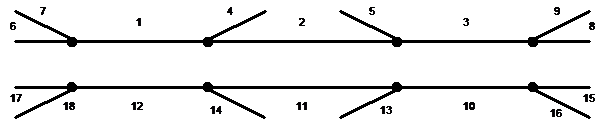

The Project Network was divided up into roads (e.g. M1, A1, etc) and each road further subdivided into junction sets. There is some variation in the configuration of the junction sets, depending on the road type. The most common type of junction set is the Motorway grade-separated junction. An example is given in Figure 1.

It can be seen that each junction set contains part of the two adjoining junction sets. Each of the assessed flows is associated with the Links (sections of carriageway) numbered from 1 to 18. The flow at Link 1 is compared with the sum of those at Links 6 and 7, with the sum of the flows at Links 2 and 4 and with the flow at Link 12. If all agree within a defined limit of accuracy, then all can be regarded as accurate. If they all disagree, the flow on Link 1 is inaccurate. If one is wrong and the others are correct, the flow on Link 1 is almost certainly accurate and the inaccuracy will be in the compared flows. All the comparisons can be verified against each other. For example, the flow at Link 2 can be verified against those at Links 3 and 5 and against that at Link 11, whilst the flow at Link 4 can be verified against that at Link 14, etc. Where inconsistencies occur, they can easily be ascribed to an individual flow. However, if there are multiple inaccuracies, the identification of the inaccurate flows may become more laborious, but these occurrences can be expected to decrease as the analysis proceeds.

The LIP is designed to run on a weekly basis. Initially, the number of undefined accuracies which were difficult to identify because of faulty equipment that returned insufficient valid data was large. However, as equipment was repaired the unknown accuracies fell considerably. The LIP produces average flows which are incorporated into map layers so that data can easily be checked with reference to the map of the Project Network. One of the key attributes that the LIP checks now that the process is maturing is whether or not the flow data has changed significantly. Where it remains essentially the same from one run to the next, the flows can be assumed to remain accurate. Where there is a significant change in the flows, the cause can be investigated.

The LIP is also useful for assisting the faults team in the rapid identification of faulty equipment.

Because the average flow in one direction is expected to be approximately the same as the flow in the opposite direction, there are cases where it is impossible to determine in which direction a particular flow has been measured. This generally occurs on rural single carriageways where the two loop sites (one for each direction) are connected to the same equipment Initially the LIP was unable to identify whether the flow data from the sites had been reversed (i.e. the flow data from a northbound site was being reported as being measured from the southbound site and vice versa). Now that the LIP is becoming mature, it has been possible to define an additional test.

This test consists of averaging the data for the morning peak and the evening peak for the 7-day period. By dividing the morning average by the evening average, a diurnal flow ratio can be derived for each flow. These can be compared with upstream and downstream ratios and checked for consistency. By checking for consistency and for flow relative to conurbations, cases of reversed flows can be identified and corrected.

The LIP has been developed at NTCC to identify inaccurate flow data on a large-scale network. Over a period of about 18 months, it has been developed and refined to the extent where the number of undefined errors is small. Work is currently under way to identify flow data that is reversed vis-à-vis the carriageway that it purports to represent. The results of applying the LIP over this period is that the accuracy has improved dramatically and, because the LIP is also useful for assisting the faults team in the rapid identification of faulty equipment, the availability of flow data has also been improved over and above what would have been expected without it.